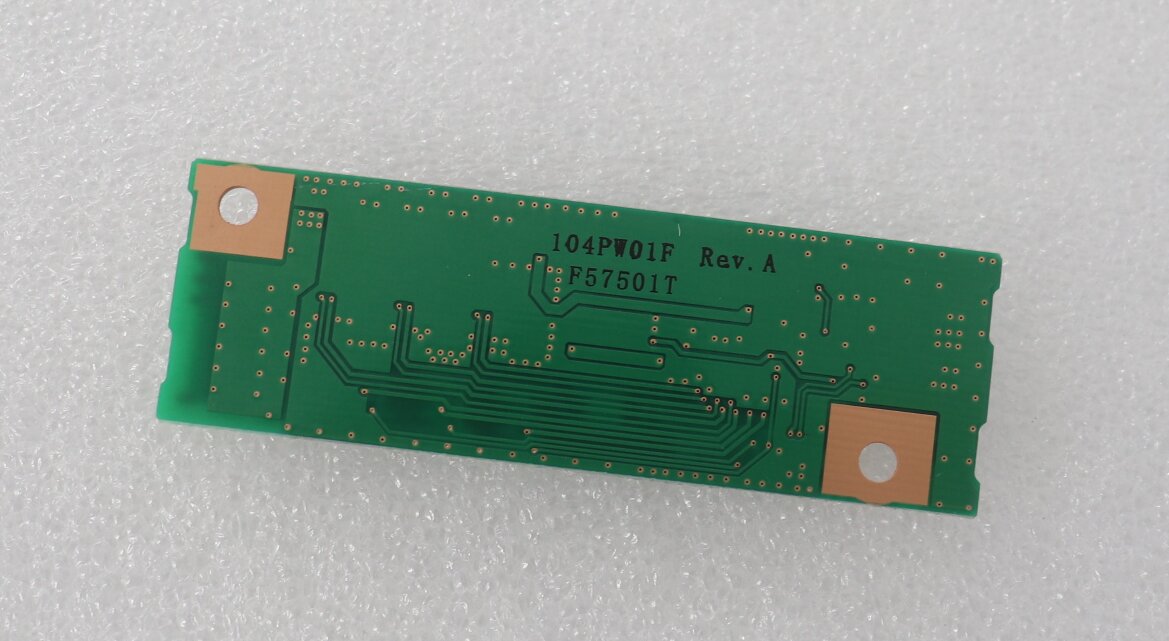

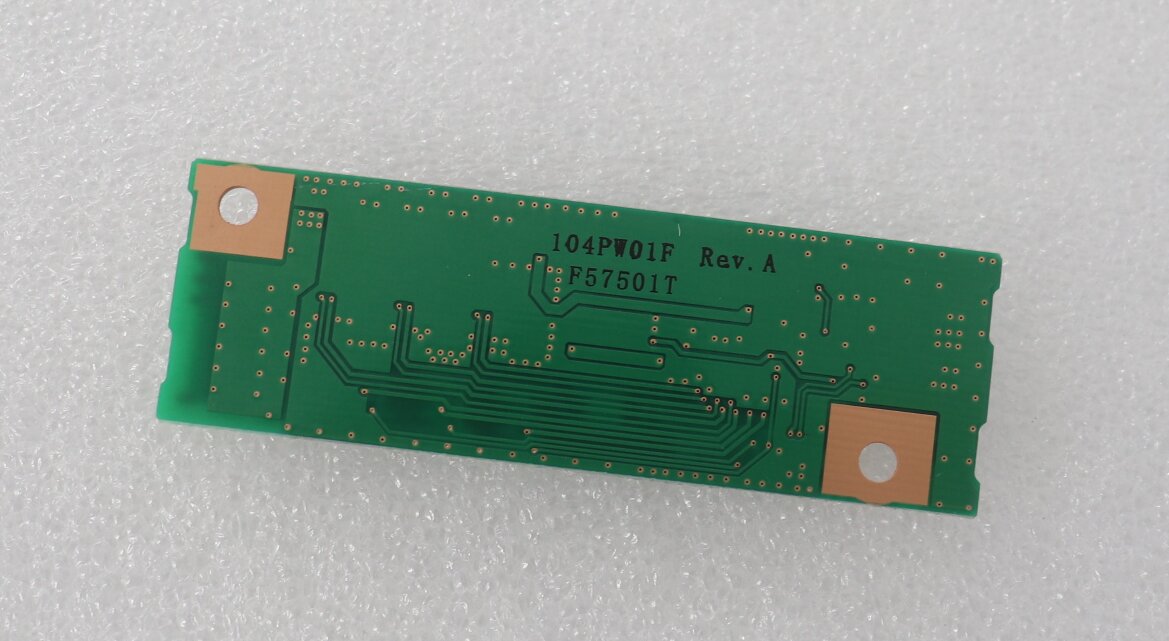

104PW01F NEC Inverter New Original

In the intricate world of industrial automation and precision control, the reliability and performance of core components are non-negotiable. At the heart of countless motion control systems lies a critical device: the inverter. This article delves deep into the specifics of one such high-caliber component—the 104PW01F NEC Inverter. As a "New Original" product, it represents the pinnacle of factory-fresh quality, guaranteed performance, and direct lineage from the renowned manufacturer, NEC.

Our exploration will move beyond a simple datasheet review. We will unravel the technical DNA of the 104PW01F, examining its architectural design, key operational parameters, and the distinct advantages it holds over generic or refurbished alternatives. Furthermore, we will contextualize its application within modern industrial ecosystems, address critical considerations for integration and procurement, and project its role in the evolving landscape of smart manufacturing. This comprehensive guide aims to serve as an authoritative resource for engineers, procurement specialists, and maintenance professionals seeking to make informed decisions about this vital piece of automation technology.

· Decoding the 104PW01F: Technical Architecture and Core Functionality

The

104PW01F is not merely a part number; it is a designation for a sophisticated power conversion and motor control device. As an inverter, or Variable Frequency Drive (VFD), its primary function is to control the speed and torque of an AC induction motor by varying the frequency and voltage of the power supplied to it. The "NEC" branding signifies its origin from NEC Corporation, a global leader in electronics and IT solutions with a long history in reliable industrial components.

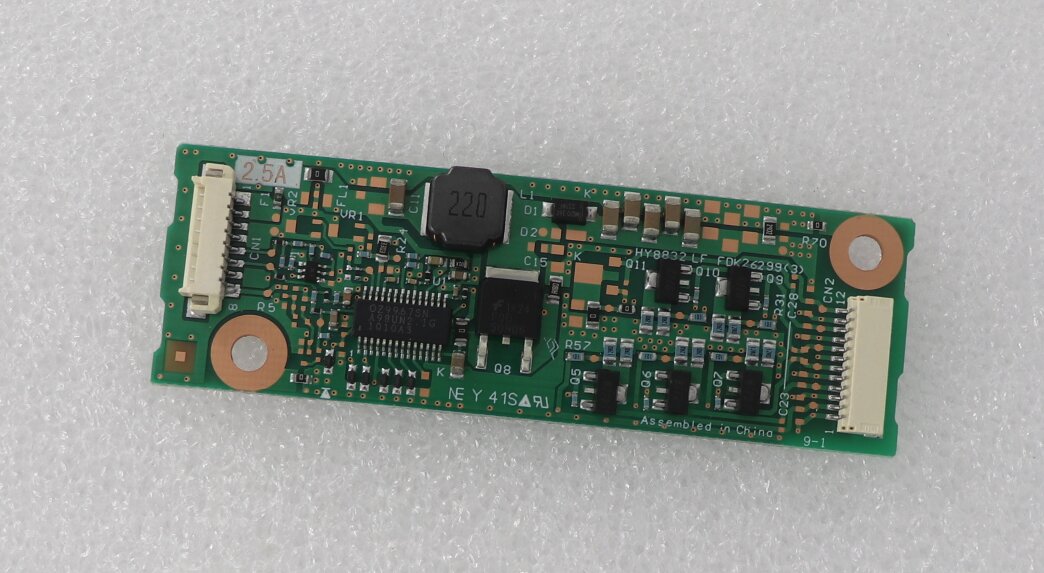

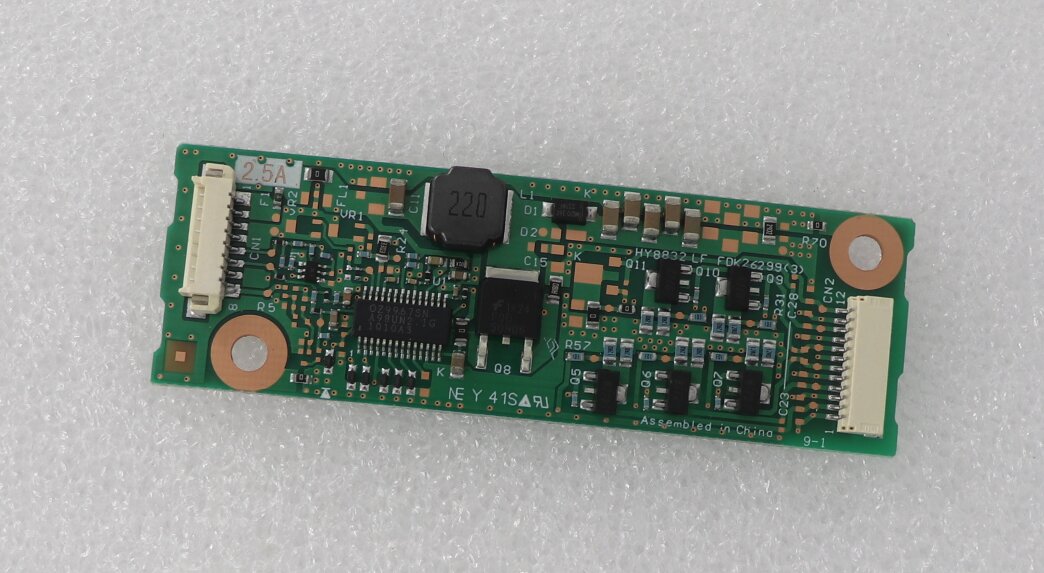

Internally, the inverter's architecture is built around advanced power electronics. It typically consists of a rectifier section that converts incoming AC line power to DC, a DC bus with filtering capacitors to smooth the voltage, and an inverter section utilizing Insulated-Gate Bipolar Transistors (IGBTs). These IGBTs are precisely switched by a microprocessor-controlled pulse-width modulation (PWM) algorithm to synthesize a variable-frequency, variable-voltage AC output. This precise control is what allows for smooth motor acceleration, deceleration, and efficient operation at speeds other than the standard line frequency.

· The Imperative of "New Original": Quality, Reliability, and Warranty

The designation "New Original" carries profound implications for system integrity and operational uptime. It certifies that the 104PW01F unit is a factory-new product, sourced directly from NEC or its authorized distributors, not a remanufactured, refurbished, or counterfeit item. This guarantees that all components—from the IGBT modules and capacitors to the printed circuit boards and cooling systems—are pristine and operating within their original design specifications.

Choosing a New Original inverter eliminates the risks associated with aged or substandard components found in refurbished units, such as degraded electrolyte in capacitors or latent thermal stress on solder joints. It ensures full compliance with NEC's published performance metrics, electromagnetic compatibility (EMC) standards, and safety certifications. Crucially, it comes with the manufacturer's full warranty and technical support, providing legal and operational protection that gray-market products cannot offer. This peace of mind is invaluable in critical applications where failure is not an option.

· Key Performance Parameters and Application Spectrum

To effectively specify and deploy the 104PW01F, understanding its key performance envelope is essential. While exact specifications should always be verified against the official NEC datasheet, such a drive is characterized by parameters like its voltage class (e.g., 200V or 400V AC), horsepower or kilowatt rating, output current capacity, and control frequency range. Its feature set likely includes multiple control modes (V/f, sensorless vector), programmable digital and analog I/O, and communication protocol support for integration into broader control networks.

The application spectrum for a reliable inverter like the 104PW01F is vast. It is the engine of precision in industries such as material handling (conveyors, hoists), HVAC (pumps, fans), packaging machinery, and automated production lines. In these settings, its ability to provide soft-start functionality reduces mechanical stress, while speed regulation optimizes process control and yields significant energy savings. Its robustness makes it suitable for environments where consistent performance under variable loads is demanded.

· Strategic Integration and System Compatibility

Successful implementation of the 104PW01F extends beyond physical mounting and wiring. Strategic integration involves ensuring compatibility with the existing motor's electrical characteristics and the mechanical load profile. Proper sizing is paramount—an undersized inverter will trip on overcurrent, while an oversized one represents unnecessary capital expenditure and may not control the motor optimally at lower loads.

Furthermore, integration encompasses configuring the drive's parameters to match the application's requirements. This includes setting acceleration/deceleration ramps, defining torque limits, and programming the logic for the control inputs. For modern smart factories, enabling and configuring the correct industrial communication protocol (such as Modbus, Profibus, or Ethernet/IP) is critical for seamless data exchange with PLCs and SCADA systems, enabling remote monitoring, predictive maintenance, and centralized control.

· Procurement Nuances and Supply Chain Considerations

Procuring a genuine

104PW01F NEC Inverter requires diligence. The market is populated with alternative sources offering varying degrees of claim regarding authenticity. The most secure path is through NEC's official distribution channels or long-established, authorized industrial automation suppliers. They provide traceability, often with serial number verification, ensuring the product is genuine and eligible for support.

Supply chain considerations are also crucial. Lead times for new original components can fluctuate based on global manufacturing and logistics trends. Planning ahead and building relationships with reputable suppliers can mitigate project delays. It is also advisable to confirm the exact firmware version and hardware revision upon purchase, as these can impact compatibility with specific motors or communication setups. The upfront cost of a New Original unit is an investment in reduced total cost of ownership through reliability and longevity.

· The Future Trajectory: Inverters in Industry 4.0

The role of the industrial inverter is evolving from a standalone motor controller to an intelligent node in the Industrial Internet of Things (IIoT). Future iterations and the ecosystem surrounding drives like the 104PW01F will increasingly emphasize connectivity, data analytics, and cybersecurity. Embedded sensors and advanced diagnostics will facilitate predictive maintenance, alerting operators to potential issues like bearing wear or insulation degradation before they cause downtime.

Integration with cloud platforms will allow for fleet-wide performance benchmarking and energy management. For the 104PW01F, this means its value proposition will expand beyond its core control function. It will become a source of actionable operational intelligence, contributing to smarter, more efficient, and more resilient manufacturing operations. Understanding this trajectory helps organizations future-proof their investments in automation infrastructure.

· Frequently Asked Questions (FAQs)

1. What exactly is the 104PW01F?It is a specific model of a New Original Variable Frequency Drive (VFD/inverter) manufactured by NEC, used for precise control of AC motor speed and torque.

2. Why is "New Original" status so important?It guarantees factory-fresh quality, full performance per specifications, manufacturer's warranty, and eliminates risks from used or counterfeit components.

3. What are the main applications for this inverter?Common applications include conveyor systems, pumps, fans, packaging machines, and other industrial automation requiring controlled motor motion.

4. How do I ensure I'm buying a genuine unit?Purchase only from NEC-authorized distributors or highly reputable industrial suppliers who provide traceability and authenticity guarantees.

5. Can the 104PW01F communicate with a factory PLC?Yes, it likely supports standard industrial communication protocols (e.g., Modbus, Profibus) for integration into automated control systems.

6. What are the key parameters to check before installation?Verify the voltage rating, power/current rating, and that it is compatible with your motor's specifications and load requirements.

7. Does it offer energy-saving benefits?Yes, by allowing motors to run only at the needed speed, it significantly reduces energy consumption compared to constant-speed operation.

8. What is the difference between an inverter and a servo drive?Inverters like the 104PW01F typically control speed/torque of standard AC motors, while servo drives provide ultra-precise position control for specialized motors.

9. How critical is proper parameter configuration?Extremely critical. Incorrect settings can lead to poor performance, motor damage, or drive faults. Always refer to the manual and application needs.

10. Is technical support available for this model?Yes, full technical support is available from NEC and its authorized partners, but this is typically contingent on purchasing a genuine New Original product.

Conclusion

The

104PW01F NEC Inverter stands as a testament to the critical importance of quality and precision in industrial automation. Our deep dive has revealed that it is far more than a simple component; it is a sophisticated control system whose "New Original" status forms the bedrock of system reliability, performance, and long-term operational cost-effectiveness. From its robust technical architecture to its strategic role in modern and future-facing industrial applications, this drive represents a pivotal investment in operational excellence.

In a landscape where downtime is measured in significant financial loss, the value of a genuine, fully-supported, and correctly integrated inverter cannot be overstated. By prioritizing authenticity, understanding its technical and application fit, and planning for its role within connected systems, engineers and decision-makers can harness the full potential of the 104PW01F. It is a choice that powers not just motors, but the very efficiency and intelligence of modern manufacturing.