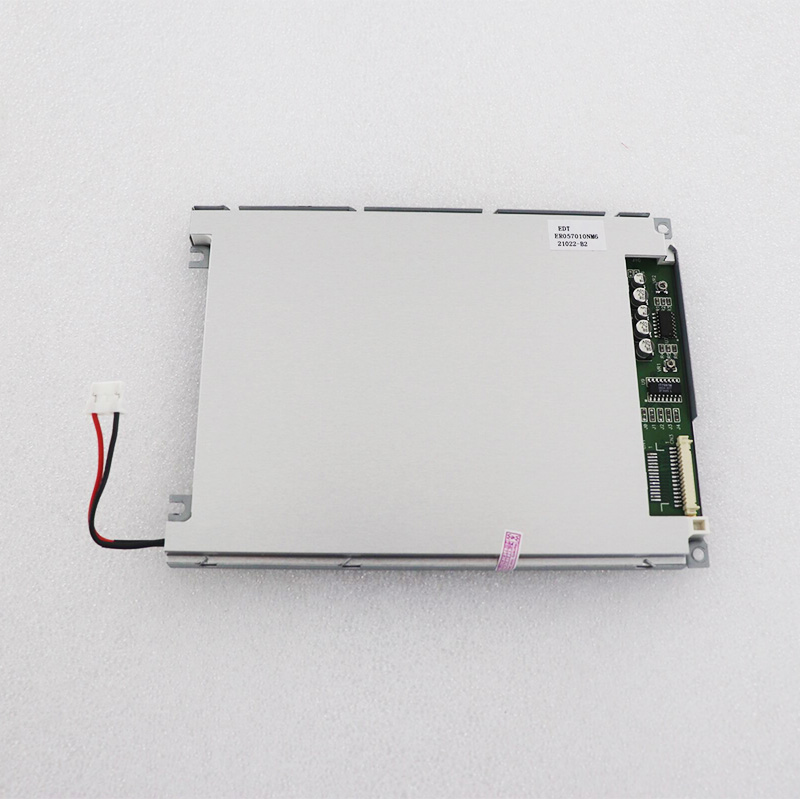

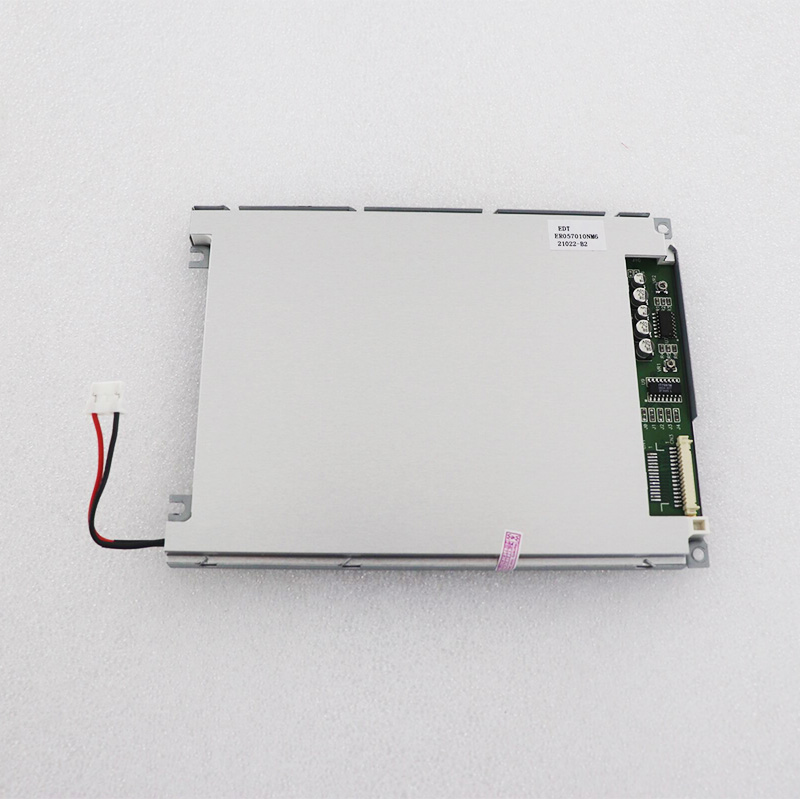

This article provides a deep-dive analysis of the ER057010NM6 panel. We will move beyond the basic datasheet to explore its architectural advantages, the practical implications of its unique resolution and size, and its suitability for harsh environments. We will dissect its interface technology, compare it with prevailing alternatives, and project its role in the future of human-machine interfaces (HMIs). This exploration is designed for engineers, product designers, and procurement specialists seeking a display solution that prioritizes reliability, readability, and seamless integration in demanding contexts. Decoding the Specification: The Rationale Behind 5.7" and QVGA

The ER057010NM6’s 5.7-inch diagonal and 320x240 (QVGA) resolution are not arbitrary choices but deliberate engineering decisions. In the world of industrial and embedded displays, physical size directly correlates with data density and panel durability. The 5.7-inch form factor offers substantial screen real estate for complex control interfaces or multi-parameter monitoring without dominating the device footprint, making it ideal for panel-mounted equipment. The QVGA resolution, while considered low by consumer smartphone standards, is a strategic asset here. It ensures exceptional character and graphic legibility without requiring excessive processing power or high-speed memory bandwidth from the host microcontroller unit (MCU). This translates to lower system cost, reduced power consumption, and simplified driver development. The 4:3 aspect ratio is another key feature, perfectly suited for traditional menu systems, numerical data presentation, and schematic diagrams commonly found in industrial settings, avoiding the wasted space or distorted graphics that can occur with widescreen formats.

Core Technology and Optical Performance Breakdown

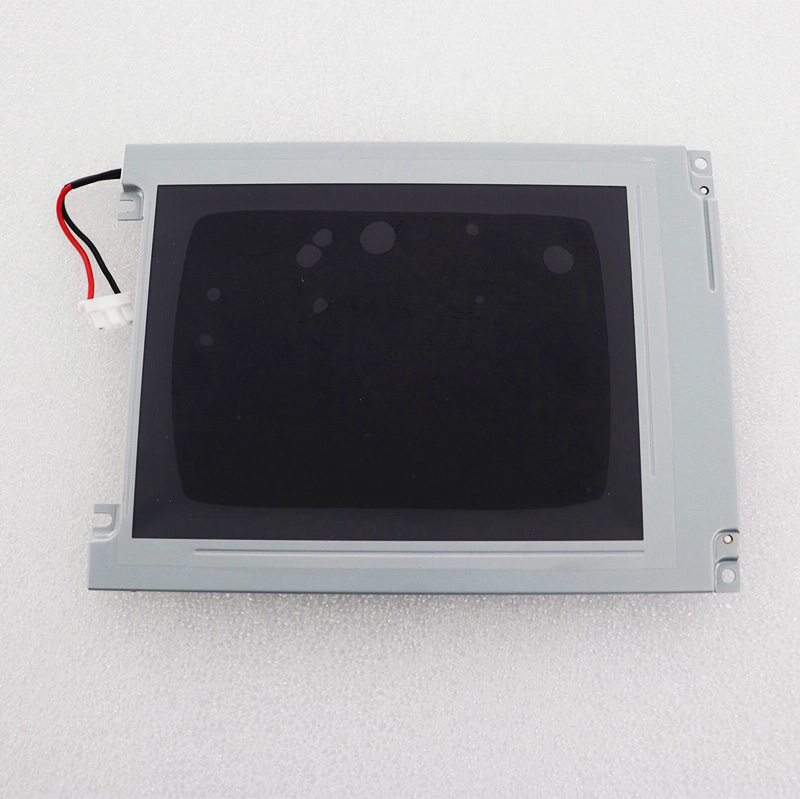

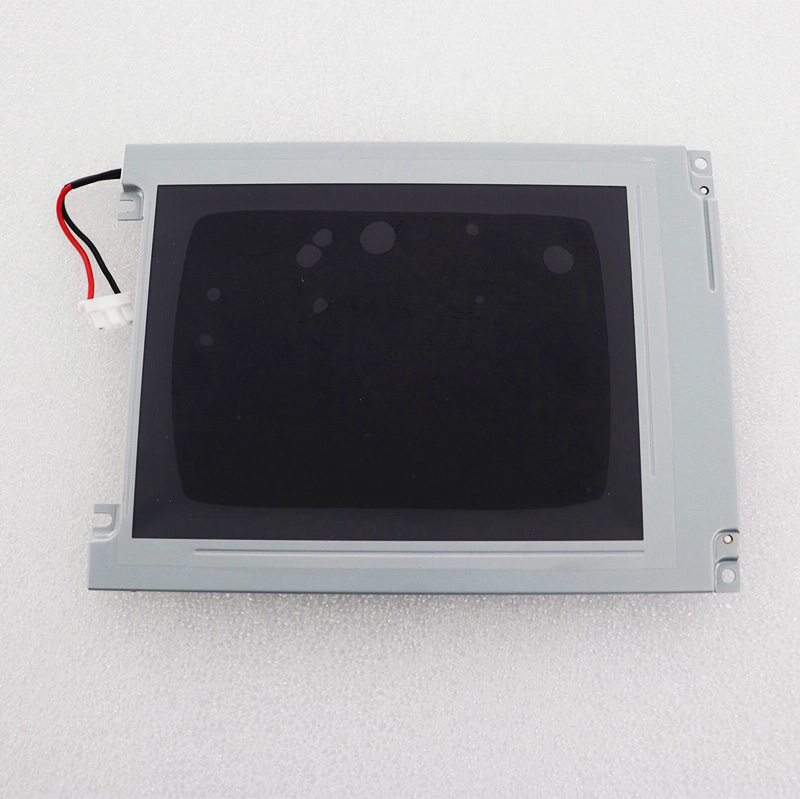

At the heart of the ER057010NM6 is a high-performance Twisted Nematic (TN) or potentially an advanced Thin-Film Transistor (TFT) LCD matrix, engineered for clarity and consistency. The panel typically features a high contrast ratio, crucial for distinguishing fine details and grayscale levels in variable lighting. Its brightness specification, often in the range of 300-400 nits, ensures viewability under standard indoor office lighting and many factory conditions. Optical enhancements are a critical differentiator. The panel likely incorporates a robust anti-glare (AG) surface treatment. This treatment diffuses ambient light, drastically reducing reflections and preventing the "mirror effect" that can render displays unusable under bright lights. Furthermore, the viewing angles—both horizontal and vertical—are optimized for the typical use case where an operator may view the screen from a slightly off-center position, ensuring color and contrast stability. The choice of a transmissive or transflective backlighting scheme also plays a role in its intended application environment.

Robustness for Demanding Environments: Built to Last

The true value of a panel like the ER057010NM6 is proven outside the lab. Its construction is inherently geared towards reliability. Operating and storage temperature ranges are wide, often spanning from -20°C or -30°C to +70°C or higher, guaranteeing functionality in unheated enclosures or under direct sun load. The mechanical design focuses on resilience against vibration and shock, common in automotive, aerospace, or heavy machinery applications. Longevity is a key selling point. The backlight system utilizes long-life LEDs, rated for tens of thousands of hours of continuous operation, minimizing maintenance and downtime risks. The entire assembly is designed to resist the ingress of dust and moisture, with some versions offering enhanced sealing. This environmental hardening makes it a preferred choice over commercial-grade displays, which would quickly fail in similar conditions, leading to costly system failures and safety concerns.

Integration Architecture: The RGB Interface Advantage

The ER057010NM6 commonly features a parallel RGB (Red, Green, Blue) interface, a critical aspect for seamless integration. This interface type allows for direct connection to a vast ecosystem of microcontrollers (MCUs) and microprocessors (MPUs) that include integrated LCD controllers, such as many ARM Cortex-M series chips or legacy processors. The parallel interface provides a straightforward, low-latency data path. For developers, this means avoiding the complexity and cost of additional controller chips or serialization/deserialization components. The direct drive capability simplifies the board design, reduces the bill of materials (BOM), and shortens development cycles. This "plug-and-play" compatibility with common embedded processor outputs is a significant advantage over panels requiring complex LVDS or MIPI interfaces, which demand more powerful and expensive host processors and more intricate PCB layout skills.

Comparative Landscape: Positioning Against Alternatives

Understanding the ER057010NM6 requires contextualizing it against common alternatives. Compared to larger 7-inch or 10-inch panels, it offers a more compact and cost-effective solution for devices where space and budget are constrained. Against higher-resolution displays (like 480x272 or 800x480), it demands less from the host system, enabling the use of lower-tier MCUs and reducing overall power draw—a vital factor for battery-powered or energy-sensitive devices. Its most significant contrast is with OLED technology. While OLEDs offer superior contrast and viewing angles, they historically face challenges with longevity (burn-in), higher cost, and performance degradation in extreme temperatures. The ER057010NM6’s LCD technology provides predictable, stable performance over a long lifespan in varied environments, making it the more reliable, "set-and-forget" choice for mission-critical industrial equipment where failure is not an option.

The Future Niche: Sustained Relevance in an Evolving Market

In a market chasing higher pixel densities and flexible form factors, the ER057010NM6 carves out a sustainable and growing niche. The drive towards industrial automation (Industry 4.0), IoT edge devices, and modernized legacy machinery creates consistent demand for durable, no-nonsense display interfaces. This panel is perfectly aligned with these trends, serving as the primary or secondary HMI for sensors, controllers, test equipment, and medical devices. Its future is not about becoming obsolete but about continued refinement. We can expect to see iterations with improved power efficiency via better backlight drivers, wider temperature tolerances, and potentially integrated touch solutions (resistive or projected capacitive) that maintain the same rugged pedigree. As long as there is a need for dependable, readable, and easy-to-integrate displays in controlled or harsh environments, panels like the ER057010NM6 will remain essential components in an engineer's toolkit. Frequently Asked Questions (FAQs)

Q1: What is the primary application for the ER057010NM6 display?A: It is designed for industrial, medical, instrumentation, and embedded systems where reliability, readability, and wide temperature operation are crucial.

Q2: Why choose a 320x240 (QVGA) resolution today?A: QVGA reduces MCU processing load, lowers system cost and power consumption, and provides excellent legibility for text and simple graphics.

Q3: What type of interface does this panel use?A: It typically uses a parallel RGB interface, allowing direct connection to many common microcontrollers without extra controller chips.

Q4: Is this panel suitable for outdoor use?A: With sufficient brightness (nits) and a strong anti-glare treatment, it can be used in some outdoor conditions, but direct sunlight viewability should be verified.

Q5: What are the key advantages over a consumer LCD?A: Industrial-grade components, wide operating temperature range, vibration resistance, long-life backlight, and design for 24/7 operation.

Q6: Does it support touch functionality?A: The core panel may not, but it is often available as a variant or can be easily paired with a separate resistive or capacitive touch overlay.

Q7: How does it compare to an OLED display?A: It trades perfect blacks and viewing angles for superior longevity, temperature resilience, lower cost, and no risk of burn-in.

Q8: What is the typical lifespan of the backlight?A: Backlight LEDs are often rated for 50,000 hours or more, ensuring years of continuous operation.

Q9: Can it be driven by a single-board computer like a Raspberry Pi?A: Yes, but it may require a specific adapter board to convert the Pi's video output (like HDMI or DSI) to the panel's parallel RGB input.

Q10: Where can I find technical documentation for integration?A: Detailed datasheets, pinout diagrams, and initialization sequences are typically provided by the manufacturer or authorized distributors.

Conclusion

The ER057010NM6 5.7-inch LCD panel is a compelling testament to the principle that optimal technology is not always about the highest specs, but about the perfect fit for a specific purpose. Its deliberate design choices—from the pragmatic QVGA resolution and 4:3 aspect ratio to the ruggedized construction and MCU-friendly RGB interface—converge to create a solution of exceptional utility for the embedded and industrial worlds. For designers and engineers, this panel represents a low-risk, high-reliability component that simplifies development, ensures durability, and delivers consistent performance where it matters most. In an age of rapid technological change, the ER057010NM6 secures its place by mastering the fundamentals of clarity, resilience, and integration, proving that specialized, purpose-driven innovation holds enduring value.