- Industrie-LCD-Display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO

- INTEL

- Key board

- FAIRCHILD

- Der Aufsichtsrat

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- Omron

- Relais.

- Der controller

- Optoelektronische schalter

- Optoelektronische sensoren

- Original

- Fan

- Motortreiber

- Endschalter

- Verstärker

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformator

- Fiber Optic Sensor

- Schutzrelais

- Temperaturregler

- Näherungsschalter

- Switch Sensor

- Siemens

- PCB

- HMI Touch-Glas

-

HMI-Vollautomat Ganze Einheit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley Automatisierung HMI Touch

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- andere

- Module

- LCD Wechselrichter

- Membran Tastenfeld Schalter

- Winni Touch Screens

- Frequenzumrichter

- Servo Motor

- PLC

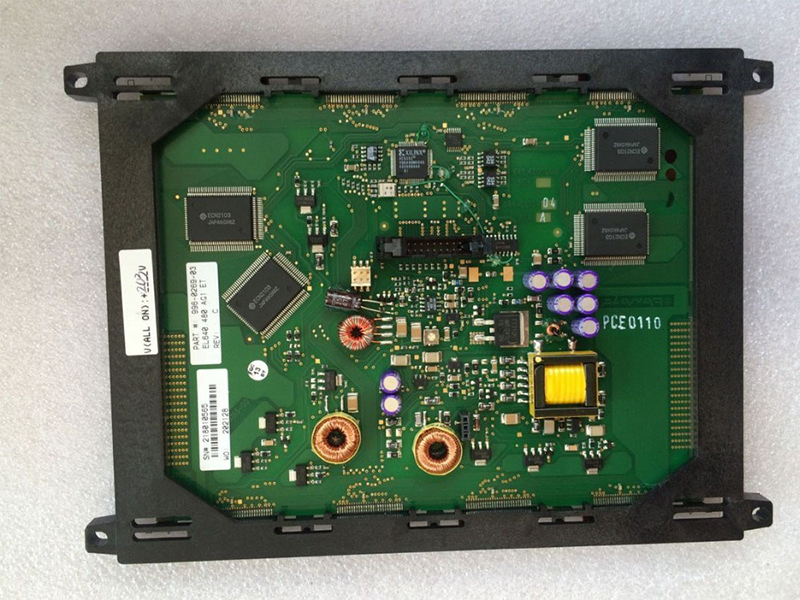

8.4" a-Si STN-LCD Panel 640x480 for PLANAR EL640.480-AG1

In the intricate world of industrial and medical display technology, the selection of a specific panel is often a critical engineering decision with far-reaching implications. This article delves into the technical universe and application significance of a specialized component: the a-Si STN-LCD Panel, 8.4-inch diagonal, with a resolution of 640 x 480 pixels, designed as a replacement or core element for the PLANAR EL640.480-AG1 ET display module. This particular specification represents a mature yet persistently vital technology in sectors where reliability, readability, and cost-effectiveness are paramount.

We will explore the foundational technology of amorphous Silicon (a-Si) Thin-Film Transistor (TFT) STN (Super Twisted Nematic) LCDs, unpacking why this combination remains relevant. Moving beyond generic descriptions, the analysis will focus on the specific performance characteristics of the 8.4" VGA format, its typical operating parameters, and the key interface considerations. Furthermore, we will examine the primary industrial and medical applications that demand such a panel, concluding with practical guidance on integration, sourcing, and lifecycle management for engineers and procurement specialists tasked with maintaining legacy systems or designing new, cost-optimized solutions.

Understanding the a-Si STN-LCD Technology Foundation

At the core of this panel lies amorphous Silicon (a-Si) Thin-Film Transistor (TFT) technology acting on a Super Twisted Nematic (STN) liquid crystal layer. Unlike the more common a-Si TFT LCDs using Twisted Nematic (TN) or In-Plane Switching (IPS) modes for consumer electronics, the STN variant employs a liquid crystal twist angle of 180 to 270 degrees. This super-twist creates a steeper electro-optical response curve, which is crucial for achieving higher contrast and better multiplexing capability with simpler drive electronics.

The use of a-Si TFTs as the active matrix addressing scheme provides precise control over each pixel, eliminating the crosstalk and ghosting issues prevalent in passive matrix STN displays. This marriage results in a display that offers superior optical performance—specifically high contrast and wide viewing angles—compared to passive STN, while typically being more cost-effective and power-efficient than IPS-based TFT modules of similar size. This makes it an ideal candidate for applications where visual clarity under various lighting conditions is essential, but budget and power constraints are also significant factors.

Decoding the 8.4-Inch VGA (640x480) Format

The 8.4-inch diagonal measurement and 640 x 480 pixel (VGA) resolution form a classic and highly optimized format in the industrial landscape. The 4:3 aspect ratio is inherently well-suited for displaying traditional user interfaces, data readouts, and diagnostic imagery without wasteful black bars. With a pixel pitch of approximately 0.267mm, this configuration delivers a balance between information density and readability, preventing the need for excessive zooming or scrolling in control applications.

The VGA resolution, while considered low by modern consumer standards, remains a powerful workhorse in embedded systems. It demands less from the host system's graphical processing unit and frame buffer memory, reducing overall system cost and complexity. For the PLANAR EL640.480-AG1 ET module, this specific panel is the visual engine, defining its physical footprint and native input signal requirement. Understanding this format is key to ensuring compatibility with existing graphic controllers and software designed for VGA output, a common feature in many industrial PCs and microcontrollers.

Key Performance Characteristics and Specifications

Evaluating this a-Si STN-LCD panel requires a deep dive into its datasheet parameters. Key optical specs include a typical contrast ratio (often in the range of 300:1 to 500:1 for STN), which ensures sharp differentiation between foreground and background elements. Brightness levels, typically measured in nits (cd/m²), are tailored for indoor use under controlled or moderately bright lighting. The STN technology, especially when coupled with a proper backlight, provides consistent viewing angles (often 80/80/80/80 min for Left/Right/Up/Down) crucial for panels viewed from off-axis positions.

Electrical characteristics are equally vital. The panel operates on a defined supply voltage (e.g., 3.3V or 5V for logic, and a higher voltage for the backlight inverter). Its power consumption is a critical factor for portable or energy-sensitive devices. Furthermore, the operating and storage temperature ranges are designed to meet industrial standards, ensuring functionality in environments where commercial-grade panels would fail. These specs directly dictate the panel's reliability and suitability for harsh conditions.

Interface and Integration Considerations

Integrating this 8.4" panel into a system like the PLANAR module involves careful attention to its interface. Typically, these panels utilize an LVDS (Low-Voltage Differential Signaling) or earlier TTL (Transistor-Transistor Logic) digital interface to receive pixel data from the controller board. The pinout, signal timing, and voltage levels must be meticulously matched to the host controller's output.

Additionally, the backlight system—usually CCFL (Cold Cathode Fluorescent Lamp) or, in newer iterations, LED-based—requires a dedicated power supply and inverter/driver circuit. Mechanical integration involves securing the panel within a bezel or chassis, often using standardized mounting holes, while ensuring proper grounding and protection from electrostatic discharge (ESD). Understanding these electrical and mechanical interfaces is paramount for a successful replacement or new design, preventing signal integrity issues or physical damage.

Primary Industrial and Medical Applications

The robustness and clarity of this a-Si STN-LCD panel make it a preferred choice in demanding sectors. In industrial automation, it serves as the human-machine interface (HMI) for programmable logic controllers (PLCs), CNC machine controls, and test/measurement equipment, where legibility under factory lighting and long operational life are critical.

In the medical device field, this technology is found in patient monitoring systems, diagnostic equipment, and portable clinical devices. The high contrast and stable performance are essential for accurately displaying waveforms, numerical data, and low-resolution diagnostic images. Its reliability ensures compliance with stringent medical equipment standards. Other applications include point-of-sale systems, transportation dashboards, and specialized instrumentation, where the combination of performance, durability, and cost creates an optimal value proposition.

Sourcing, Compatibility, and Lifecycle Management

For engineers maintaining systems built around the PLANAR EL640.480-AG1 ET, sourcing the correct panel is a strategic task. It involves verifying not just the physical size and resolution, but also the exact interface type, backlight technology, and mechanical dimensions to ensure drop-in compatibility. Procuring from authorized distributors or reputable specialists is crucial to avoid counterfeit or off-spec components that can compromise system integrity.

Given that this technology represents a mature product, lifecycle management is a key concern. Proactive strategies include securing lifetime buys for long-term projects, identifying qualified alternative sources, or planning for eventual upgrades to next-generation panels (like TFT IPS) with appropriate adapter solutions. Effective management mitigates the risk of production halts due to component obsolescence, ensuring the continued serviceability of critical equipment for years to come.

FAQs

Q10: Is this technology becoming obsolete?A10: While mature, it is far from obsolete in its target markets. However, proactive lifecycle planning is essential due to the natural progression of display technologies.

Conclusion

The 8.4-inch a-Si STN-LCD panel with 640x480 resolution exemplifies a class of display technology where proven reliability, optical performance, and economic efficiency converge. As the core component of modules like the PLANAR EL640.480-AG1 ET, it continues to empower critical systems across industrial automation, medical instrumentation, and beyond. Its value lies not in chasing the latest consumer trends, but in delivering unwavering performance in environments where failure is not an option.

For engineers and procurement professionals, a thorough understanding of its technical underpinnings, integration requirements, and application landscape is indispensable. This knowledge enables informed decision-making, from selecting the correct replacement to planning for the future lifecycle of embedded systems. In a world increasingly focused on the new, this panel stands as a testament to the enduring power of optimized, purpose-driven technology.