- Industrie-LCD-Display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO

- INTEL

- Key board

- FAIRCHILD

- Der Aufsichtsrat

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- Omron

- Relais.

- Der controller

- Optoelektronische schalter

- Optoelektronische sensoren

- Original

- Fan

- Motortreiber

- Endschalter

- Verstärker

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformator

- Fiber Optic Sensor

- Schutzrelais

- Temperaturregler

- Näherungsschalter

- Switch Sensor

- Siemens

- PCB

- HMI Touch-Glas

-

HMI-Vollautomat Ganze Einheit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley Automatisierung HMI Touch

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- andere

- Module

- LCD Wechselrichter

- Membran Tastenfeld Schalter

- Winni Touch Screens

- Frequenzumrichter

- Servo Motor

- PLC

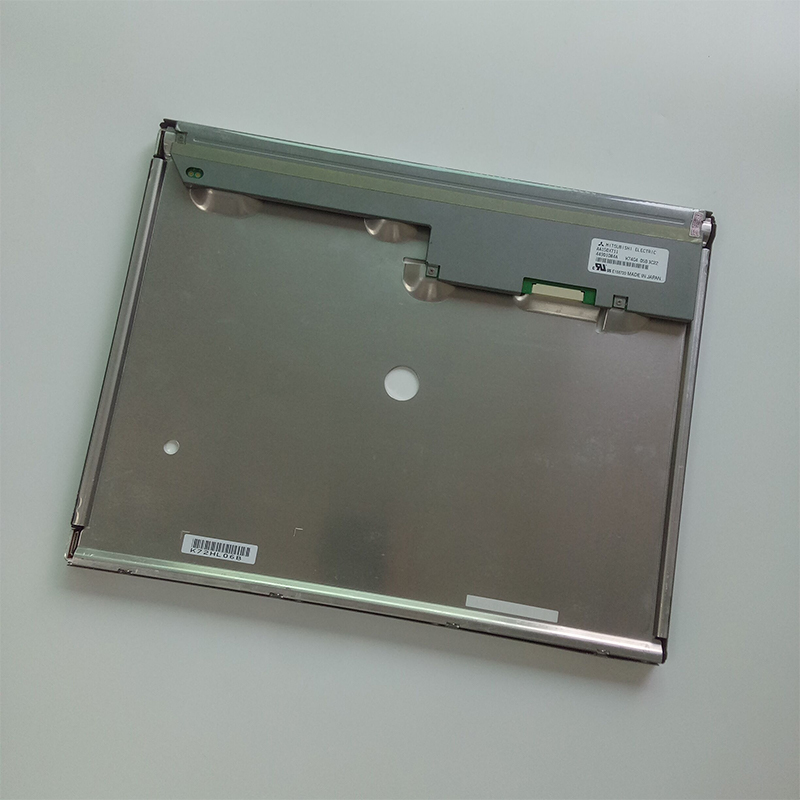

AA150XT11 New and Original Mitsubishi 15inch 1024*768 LCD Display

In the intricate world of industrial automation, medical imaging, and specialized display applications, the choice of a display panel is far more than a simple matter of screen size. It is a critical decision that impacts system reliability, image clarity, and long-term operational stability. At the heart of many such demanding systems lies a component like the AA150XT11, a 15-inch LCD display module originally manufactured by Mitsubishi Electric.

This article delves deep into the significance of the AA150XT11, moving beyond basic specifications to explore its technical legacy, inherent value, and the crucial considerations surrounding its procurement and application. We will examine why this specific model, with its 1024x768 (XGA) resolution, continues to be a sought-after component in legacy and specialized systems, and what "new and original" truly means in the context of industrial-grade electronics. Understanding these facets is essential for engineers, procurement specialists, and system integrators tasked with maintaining peak performance in critical environments.

The Enduring Legacy of Mitsubishi's Industrial Display Technology

The AA150XT11 is not merely a display; it is a product of Mitsubishi Electric's profound heritage in high-reliability industrial and professional display solutions. Mitsubishi has long been synonymous with durability, precision, and performance in sectors where failure is not an option. This module was engineered during an era when displays were built as core system components, designed to withstand continuous operation, varying thermal conditions, and mechanical stress.

Its legacy is defined by a commitment to consistent quality and technical excellence. The panel utilizes a high-grade a-Si TFT LCD process, known for its stability and mature manufacturing technique. This historical context is vital; it explains why this specific model remains in demand long after its initial production run. Systems originally designed around the AA150XT11 rely on its exact electrical, optical, and physical characteristics for seamless operation, making genuine replacements a necessity rather than a preference for maintaining system integrity and avoiding costly requalification processes.

Decoding the Specifications: More Than Just 1024x768

While the 15-inch diagonal and XGA (1024x768) resolution are headline figures, the true depth of the AA150XT11 lies in its detailed parameter set. The 4:3 aspect ratio is a hallmark of many industrial control panels and medical monitors, perfectly suited for data-rich interfaces and standard-definition imaging. The specification sheet reveals critical details such as luminance (brightness), contrast ratio, viewing angles, and color gamut, all tuned for professional readability.

Furthermore, its interface—typically a LVDS (Low-Voltage Differential Signaling) input—is a standard for robust, noise-resistant data transmission in industrial environments. The module's mechanical design, including bezel dimensions, mounting hole patterns, and connector placement, is also part of its specification. This mechanical conformity is as crucial as the electrical interface, ensuring drop-in compatibility. For engineers, a deep understanding of these specs is the first step in verifying compatibility and forecasting performance in the target application.

The Critical Importance of "New and Original" in Component Sourcing

In the secondary electronics market, the terms "new" and "original" carry significant weight and specific meanings, especially for a component like the AA150XT11. "Original" unequivocally means the display was manufactured by Mitsubishi Electric or an authorized fab under its strict quality control. It guarantees the component meets all published datasheet specifications and reliability standards.

"New" in this context typically refers to new old stock (NOS) or factory-fresh components that have never been soldered or used in an end application. They are pristine, with original packaging and no operational hours. The insistence on "new and original" stems from risk mitigation. Counterfeit, refurbished, or remarked displays may have hidden defects, reduced lifespan, or subtle performance deviations that can cause system failures, calibration drift in medical equipment, or inconsistent performance in automation. For mission-critical systems, the premium for authenticity is a justified investment in reliability.

Primary Application Sectors and Use Case Scenarios

The AA150XT11 finds its home in environments where performance consistency trumps the allure of the latest consumer display trends. Its primary application sectors are characterized by long product lifecycles and high reliability demands.

Industrial Automation & HMI: As the operator interface for PLCs, CNC machines, and process control systems. Its rugged build and stable performance are essential for factory floor conditions.

Medical Diagnostic Imaging: Used as the display module in ultrasound machines, patient monitors, and other diagnostic devices where grayscale clarity and consistency are paramount for accurate readings.

Aviation & Transportation: Integrated into onboard information systems, control panels, and ground support equipment where component certification and reliability are critical.

Specialized Test & Measurement Equipment: Serving as the visual output for oscilloscopes, spectrum analyzers, and other precision instruments.

Navigating the Supply Chain: Sourcing Authentic AA150XT11 Modules

Sourcing a genuine AA150XT11 requires diligence. The original Mitsubishi production has ceased, leading to a controlled supply via specialized distributors. Reputable suppliers will provide traceability, often referencing original batch codes or Mitsubishi part number documentation. They should be transparent about the component's status—whether it is NOS, pulled from unused equipment, or refurbished.

Key due diligence steps include: requesting high-resolution photos to check for authentic Mitsubishi labeling and date codes; verifying electrical functionality through basic testing; and understanding the supplier's warranty and return policy. Trusted distributors specializing in obsolete or hard-to-find industrial components are typically more reliable than general-purpose electronic part marketplaces. Building a relationship with a knowledgeable supplier is invaluable for securing authentic parts and gaining technical support.

Integration Considerations and Long-Term System Support

Successfully integrating the AA150XT11 into a system, whether for new production or as a direct replacement, involves several technical considerations. Engineers must ensure the LVDS controller board or system host is compatible with the module's pinout, voltage requirements, and timing characteristics. The mechanical integration must account for the exact bezel size and mounting points to ensure a proper fit.

For long-term support, developing a strategic inventory of these modules may be prudent for manufacturers supporting legacy systems. Alternatively, exploring form-fit-function compatible alternatives from other high-reliability manufacturers can be a risk-mitigation strategy, though this often requires careful electrical and optical validation. The goal is to ensure system longevity and serviceability for the entirety of its operational lifespan, which can extend for decades in industrial and medical fields.

FAQs: AA150XT11 LCD Display

Q10: Should I stockpile these for future repairs?A10: For businesses maintaining legacy systems, securing a small inventory of authentic modules is a recommended risk-mitigation strategy.

Conclusion

The Mitsubishi AA150XT11 LCD module exemplifies the critical role of specialized, high-reliability components in sustaining the operational life of professional and industrial systems. Its value extends far beyond its basic resolution and size, residing in its engineering heritage, precise specifications, and the guaranteed performance that comes with an authentic "new and original" unit. In sectors where system downtime is costly and performance consistency is mandatory, the integrity of every component is paramount.

Navigating the procurement and integration of such modules requires a blend of technical knowledge and supply chain vigilance. By understanding the legacy, insisting on authenticity, and planning for long-term support, engineers and organizations can ensure the continued reliability of the vital systems that depend on these precision displays. The AA150XT11 is more than a screen; it is a link to the enduring principles of quality and reliability in industrial electronics.