- Industrial LCD display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA Module

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO Module

- INTEL

- Key board

- FAIRCHILD

- Motherboard

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- OMRON

- Relay

- Controller

- Photoelectric Switch

- Photoelectric Sensor

- Original

- Fan

- Motor Driver

- Limit Switch

- Amplifier

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformer

- Fiber Optic Sensor

- Protection Relay

- Temperature Controller

- Proximity Switch

- Switch Sensor

- Siemens

- Industrial board

- HMI Touch Glass

-

HMI Full Machine Whole unit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley automation HMI Touch Panel

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- other

- Module

- lcd inverter

- Membrane Keypad Switch

- Winni Touch Screens

- Frequency Inverter

- Servo Motor

- PLC

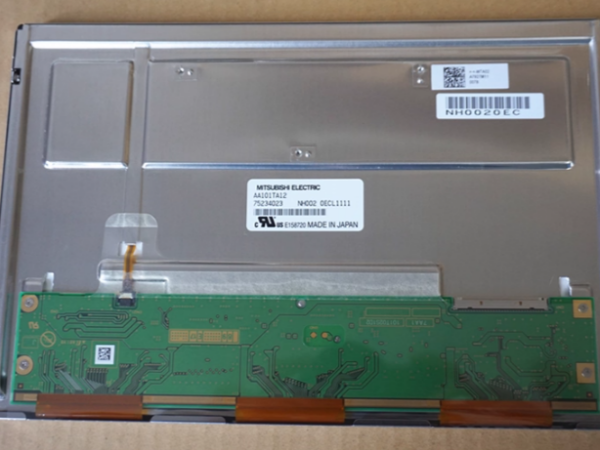

In the intricate world of industrial automation, medical imaging, and high-reliability human-machine interfaces (HMIs), the display panel is far more than a simple window to data. It is the critical touchpoint where digital commands translate into actionable visual intelligence. At the heart of many such demanding applications lies a component renowned for its precision and durability: the AA101TA12 Mitsubishi 10.1" TFT-LCD Display Module. This isn't a consumer-grade screen; it is a meticulously engineered solution designed for mission-critical environments where failure is not an option.

This article delves deep into the technical essence and application significance of the AA101TA12. We will move beyond basic specifications to explore the engineering philosophy behind its 1280x800 resolution, its robust construction, and the specific challenges it is built to overcome. From understanding its core electrical and optical characteristics to navigating the integration process and comparing it within the broader ecosystem of industrial displays, this analysis aims to provide engineers, system integrators, and procurement specialists with a comprehensive resource for evaluating this pivotal component.

Deconstructing the AA101TA12: Core Specifications and Engineering Philosophy

The Mitsubishi AA101TA12 is built upon a 10.1-inch diagonal TFT-LCD panel with a native resolution of 1280 x 800 pixels (WXGA). This 16:10 aspect ratio offers a balanced workspace, providing more vertical real estate compared to common 16:9 widescreens, which is advantageous for viewing documents, complex control software dashboards, or lengthy data logs. The module typically incorporates a high-performance CCFL or LED backlight system, ensuring uniform brightness distribution and long operational life.

Mitsubishi's engineering philosophy for this module emphasizes reliability and signal integrity. It features a low-voltage differential signaling (LVDS) interface, which is the industry standard for robust, noise-resistant data transmission over longer cable lengths within enclosures. The module is designed as a complete, drop-in unit, often including the driver board, inverter (for CCFL versions), and a sturdy metal bezel. This integrated approach reduces design complexity for the OEM, shifting the focus from display design to seamless system integration.

The Significance of 1280x800 Resolution in Industrial Contexts

Why does the specific WXGA resolution of 1280x800 matter? In industrial and professional settings, pixel density and screen real estate directly impact usability and efficiency. This resolution provides a clear, sharp image that can display fine details of schematics, small text in code, or intricate graphical user interface (GUI) elements without excessive scaling. It strikes an optimal balance between information density and component legibility.

Furthermore, this resolution allows for the effective side-by-side display of multiple application windows—such as a live feed from a machine vision camera alongside a control parameter log. It is also a "sweet spot" for compatibility, being natively supported by a wide range of single-board computers (SBCs), industrial PCs, and standard graphics controllers without requiring exotic scaling or processing power. This universality simplifies the development and maintenance of HMI systems across different machine generations.

Robustness and Environmental Durability: Built for Challenging Conditions

The AA101TA12 distinguishes itself from commercial displays through its inherent ruggedness. Industrial environments present a host of adversaries: temperature fluctuations, conductive dust, humidity, vibration, and electromagnetic interference (EMI). This module is constructed to withstand these stresses. Its components are rated for extended temperature ranges, ensuring stable operation near heat-generating machinery or in unheated facilities.

The use of an LVDS interface, as mentioned, inherently provides better noise immunity. The physical construction likely involves secure connectors and a rigid frame to prevent disconnection or damage from constant vibration. While specific ingress protection (IP) ratings depend on the final system enclosure, the module itself is designed as a reliable core for builders to integrate into their sealed HMIs, making it suitable for factory floors, medical carts, outdoor kiosks, and transportation systems.

Integration Considerations and Interface Protocols

Successfully integrating the AA101TA12 into a product requires careful attention to its electrical and physical interface. The LVDS interface uses a multi-wire differential pair to transmit clock and data signals. Designers must ensure proper impedance matching on their host controller's PCB traces to prevent signal degradation and ensure image integrity. The power supply requirements, particularly for the backlight (whether CCFL requiring high-voltage AC or LED requiring constant current), must be meticulously adhered to.

Physically, the module's dimensions, mounting hole patterns, and connector placement are critical for mechanical design. Understanding the pinout of the interface connector is paramount. Additionally, integrators must consider the control signals for features like display enable, backlight adjustment, and potentially embedded touchscreen controllers (if a variant includes it). A thorough review of the official datasheet and application notes is non-negotiable for a smooth integration process.

Application Spectrum: Where the AA101TA12 Excels

The application areas for this display module are defined by its reliability and clarity. In Industrial Automation, it serves as the primary HMI for PLCs, CNC machine controls, and robotic workcell supervision. In Medical Equipment, its stable performance is crucial for diagnostic displays, patient monitoring systems, and surgical instrument consoles where color accuracy and uptime are vital.

Furthermore, it finds use in Transportation for onboard infotainment and control systems in trains, aircraft, and heavy vehicles. It is also employed in Point-of-Sale (POS) and Kiosk systems that operate continuously in public spaces. In each case, the AA101TA12 is chosen not for flashy features, but for its predictable, long-term performance under consistent operational stress.

Comparative Landscape: Positioning Among Industrial Displays

When evaluating the AA101TA12, it's helpful to position it within the broader market. It represents a class of mature, highly reliable modules from a tier-one Japanese manufacturer. Compared to newer consumer-grade panels, it may have slightly higher power consumption or thicker bezels, but it offers far superior longevity, temperature tolerance, and technical support.

Against other industrial-grade modules, its advantages lie in Mitsubishi's reputation for quality, the specific 10.1" WXGA format, and the proven LVDS technology. Alternatives might offer different interfaces (like eDP), higher resolutions, or capacitive touchscreens. The choice ultimately hinges on the specific project's requirements for reliability, lifecycle cost, interface compatibility, and the need for a proven, low-risk component from an established supplier.

Frequently Asked Questions (FAQs)

Q10: Where can I find the technical datasheet and pinout diagram?A: These critical documents should be sourced directly from Mitsubishi Electric's official website or through their authorized technical distributors.

Conclusion

The Mitsubishi AA101TA12 10.1" TFT-LCD module exemplifies the principle that in professional and industrial applications, reliability and precision trump novelty. Its 1280x800 resolution provides an optimal blend of clarity and workspace, while its robust construction and LVDS interface ensure dependable performance in environments that would swiftly incapacitate a consumer display.

For engineers and system designers, selecting a component like the AA101TA12 is a strategic decision that impacts product longevity, maintenance costs, and end-user satisfaction. It represents a commitment to quality and a focus on core functionality. In a landscape increasingly driven by disposable technology, this module stands as a testament to engineered resilience, serving as the dependable visual interface for the critical systems that power our industrial and medical infrastructure.