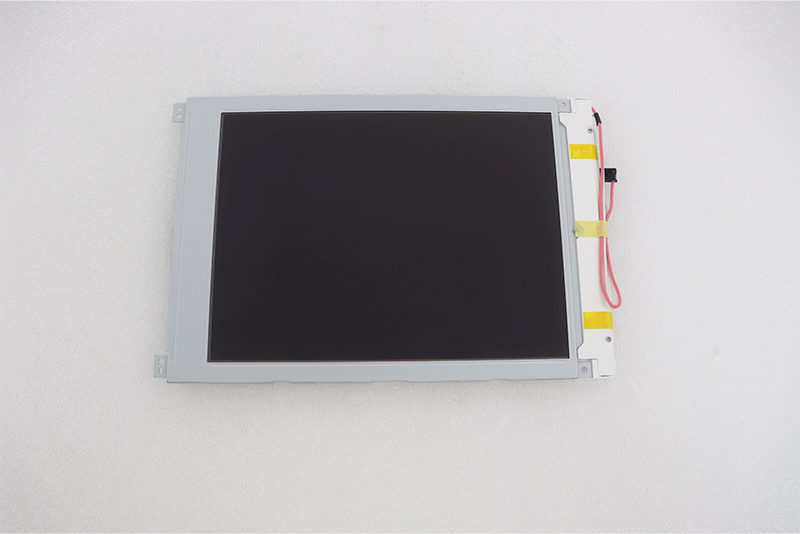

- Industrial LCD display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA Module

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO Module

- INTEL

- Key board

- FAIRCHILD

- Motherboard

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- OMRON

- Relay

- Controller

- Photoelectric Switch

- Photoelectric Sensor

- Original

- Fan

- Motor Driver

- Limit Switch

- Amplifier

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformer

- Fiber Optic Sensor

- Protection Relay

- Temperature Controller

- Proximity Switch

- Switch Sensor

- Siemens

- Industrial board

- HMI Touch Glass

-

HMI Full Machine Whole unit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley automation HMI Touch Panel

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- other

- Module

- lcd inverter

- Membrane Keypad Switch

- Winni Touch Screens

- Frequency Inverter

- Servo Motor

- PLC

Our exploration will move beyond basic specifications to uncover the engineering rationale behind its design and its practical applications. We will analyze why its 640x480 resolution remains a vital standard in industrial contexts, examine the robust features that ensure operation in demanding environments, and guide you through the key technical considerations for successful integration. This deep dive aims to provide engineers, procurement specialists, and system designers with the insights needed to evaluate whether this Optrex panel is the optimal visual interface for their challenging applications.

Understanding the Niche: The Enduring Relevance of VGA in Industrial Displays

Deconstructing the Model: A Feature Breakdown of the DMF50260NFU-FW-8

The module incorporates an LVDS (Low-Voltage Differential Signaling) interface, which provides robust, high-speed data transmission with low noise interference. The inclusion of a touch panel controller (as suggested by the "FW" designation for resistive touch) is a key differentiator, enabling direct human interaction. The mechanical design, including mounting holes and bezel dimensions, is engineered for secure integration into larger assemblies, ensuring it can withstand vibration and shock common in its target applications.

Engineering for Adversity: Ruggedization and Environmental Specifications

The panel's design likely incorporates strengthened glass and polarizers with anti-glare treatments to maintain readability under high ambient light. Its sealing and component selection are geared to resist humidity and contaminants. This ruggedization means the display won't be the point of failure in a system exposed to dust, moisture, or thermal cycling. For designers, this reliability reduces warranty claims and maintenance costs, contributing to a lower total cost of ownership despite a potentially higher initial unit cost compared to consumer-grade screens.

The Integration Imperative: Electrical and Physical Interface Considerations

Physically, integrators must adhere to the precise mechanical outline and mounting hole patterns provided in the datasheet to avoid stress on the glass. Connector type and placement are critical for cabling. Furthermore, integrating the resistive touch screen adds another layer: it requires a separate controller (often included on the panel's FPC) and drivers to interpret touch coordinates and transmit them to the host CPU via a serial interface like USB or UART. Proper planning for these electrical and mechanical interfaces is the cornerstone of a stable final product.

Application Landscapes: Where This Display Panel Excels

It is also found in transportation and logistics, such as in-vehicle telematics or forklift control panels, which experience constant vibration and temperature swings. Point-of-Service terminals in retail and hospitality benefit from its robust touch interface for high-traffic use. In each case, the panel is selected not for its pixel density, but for its proven performance under stress, its stable supply chain as a mature product, and its ability to provide a flawless user experience for years in the field.

Lifecycle and Sourcing: Navigating Obsolescence and Alternatives

Simultaneously, engineers must evaluate modern alternatives. Direct replacements might include LED-backlit versions of similar panels (often denoted by a different suffix in the model number), offering lower power consumption and mercury-free construction. In some cases, a system redesign to accommodate a newer TFT with a higher-resolution interface may be justified. The key is to perform a thorough cross-reference analysis, weighing factors like pin compatibility, optical performance, power requirements, and mechanical fit against the project's cost, timeline, and expected production lifespan.

FAQs: DMF50260NFU-FW-8 LCD Panel

Q10: Where can I find the detailed datasheet and pinout?A10: Datasheets are available through electronic component distributors' websites or by contacting display module manufacturers like Tianma (who now produces Optrex-branded panels).