- Industrial LCD display

-

Industrial Products

- DC Servo Drive

- AC Servo Drive

- other

- Heidelberg

- FANUC

- IFM

- Meter

- CCD

- Membrane Keypad

- Film

- YOKOGAWA Module

- Card

- ABB

- MITSUBISHI

- FANUC

- KEYENCE

- BECKHOFF

- Honeywell

- HOLLYSYS

- FUJI servo drives

- HP

- solenoid valve

- thermostat

- Siemens adapter

- color oscilloscope

- Fujitsu connector

- CHELIC

- SMC

- CISCO Module

- INTEL

- Key board

- FAIRCHILD

- Motherboard

- Board

- Bearing

- other

- Control Panel

- Contactor

- Circuit

- OMRON

- Relay

- Controller

- Photoelectric Switch

- Photoelectric Sensor

- Original

- Fan

- Motor Driver

- Limit Switch

- Amplifier

- power supply

- LENZE

- Cable

- Encoder

- Sensor

- Transformer

- Fiber Optic Sensor

- Protection Relay

- Temperature Controller

- Proximity Switch

- Switch Sensor

- Siemens

- Industrial board

- HMI Touch Glass

-

HMI Full Machine Whole unit

- OMRON HMI Touch Panel

- Siemens HMI Touch Panel

- Mitsubishi HMI Touch Panel

- Allen-Bradley automation HMI Touch Panel

- DELTA HMI Touch Panel

- EVIEW DELTA HMI Touch Panel

- KINCO DELTA HMI Touch Panel

- HITECH HMI Touch Panel

- WEINTECK HMI Touch Panel

- TECVIEW HMI Touch Panel

- WEINVIEW HMI Touch Panel

- PRO-FACE HMI Touch Panel

- SIMATIC HMI Touch Panel

- AMPIRE HMI Touch Panel

- HEIDELBERG HMI Touch Panel

- PANASONIC HMI Touch Panel

- PATLITE HMI Touch Panel

- KYOCERA HMI Touch Panel

- KEYENCE HMI Touch Panel

- WEINVIEW HMI Touch Panel

- HITECH HMI Touch Panel

- FUJI HMI Touch Panel

- HAKKO HMI Touch Panel

- SCHNEIDER HMI Touch Panel

- SAMKOON touch panel

- other

- Module

- lcd inverter

- Membrane Keypad Switch

- Winni Touch Screens

- Frequency Inverter

- Servo Motor

- PLC

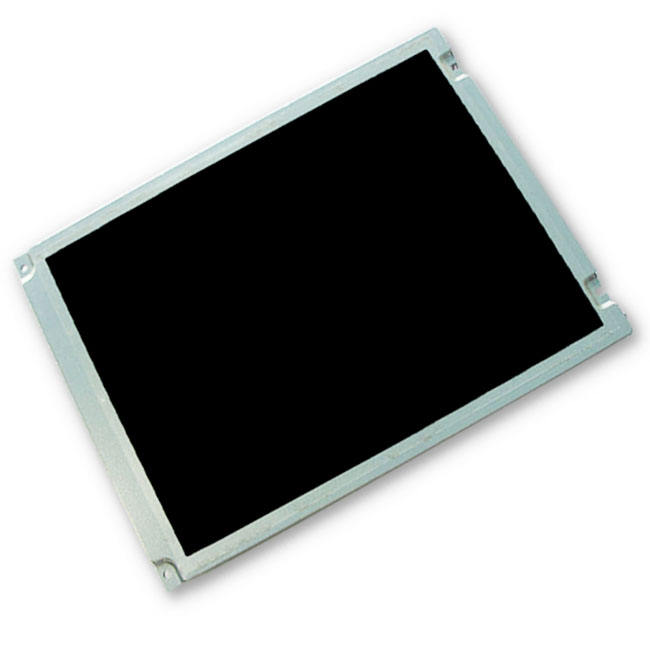

AA104VC15 Mitsubishi 10.4-inch 640*480 LCD display

In the intricate world of electronic components, the display panel often serves as the critical interface between machine and user. Its quality dictates not just the visual experience but the reliability and performance of the entire device. Among the myriad of options available to engineers and procurement specialists, the AA104VC15 LCD panel has emerged as a notable model, frequently specified for applications demanding a balance of clarity, durability, and consistent performance. But what exactly constitutes "good quality" for such a specialized component? It is a multifaceted concept that extends far beyond a simple spec sheet.

This article delves deep into the defining characteristics of a high-quality AA104VC15 LCD panel. We will move past basic part numbers to explore the material science, manufacturing rigor, and performance benchmarks that separate superior panels from mediocre ones. From the integrity of its glass substrate to the precision of its driving electronics, understanding these factors is essential for making informed sourcing decisions, ensuring product longevity, and ultimately, delivering a superior end-user experience. The pursuit of quality here is a technical imperative with direct business implications.

Decoding the AA104VC15: Core Specifications and Intended Use

The AA104VC15 is a 10.4-inch diagonal TFT LCD module with a resolution of 1024 x 768 pixels (XGA). This 4:3 aspect ratio format is a workhorse in industrial and embedded applications, from medical monitoring equipment and factory automation HMIs to point-of-sale systems and transportation displays. Its "quality" is first contextualized by its fitness for purpose. A panel destined for a climate-controlled office faces different demands than one installed on a factory floor exposed to vibration, temperature swings, and continuous operation.

Key native specifications include its brightness (typically measured in nits), contrast ratio, viewing angle (often using IPS or similar technology for wide angles), and interface type (commonly LVDS). A good quality AA104VC15 will not only meet the nominal values for these specs but will demonstrate consistency across all units in a batch. The intended use case dictates priority; a medical display may prioritize color accuracy and grayscale performance, while an outdoor kiosk would demand high brightness and robust temperature tolerance. Understanding this baseline is the first step in evaluating quality.

The Foundation of Durability: Materials and Construction

True quality is built from the inside out, starting with the materials. The glass substrate is the literal foundation. High-grade, chemically strengthened glass resists scratches, impacts, and thermal stress far better than inferior alternatives. The quality of the polarizers, optical films, and liquid crystal material itself directly affects image uniformity, color fidelity, and long-term stability. Poor materials lead to issues like image persistence, fading, or yellowing over time.

Construction integrity is equally crucial. This encompasses the precision of the cell gap, the bonding of layers, and the sealing of the panel edges. A robust construction ensures there are no air bubbles, Newton rings, or moisture ingress points. The backlight unit, often using LEDs in modern panels, must also be constructed with high-reliability components and effective thermal management. A good quality AA104VC15 exhibits flawless lamination, even backlighting without hotspots or dark corners, and a rigid, well-assembled mechanical structure that can withstand mounting stresses.

Optical Performance: Beyond Basic Brightness and Contrast

While spec sheets list brightness and contrast, a deep quality assessment probes deeper into optical performance. Brightness uniformity across the entire active area is a critical metric often overlooked; a panel with a high peak brightness but significant fall-off at the edges is of poor quality. Similarly, contrast ratio should be stable across different viewing angles, not just head-on.

Color gamut and grayscale linearity define the panel's ability to render accurate and smooth images. A quality industrial panel like the AA104VC15 should have stable white point coordinates and precise gamma curve tracking. The absence of visual artifacts is paramount: no dead or stuck pixels (typically governed by a pixel defect policy like ISO 9241-307), minimal flicker, and no image ghosting or smearing during dynamic updates. These optical characteristics are the direct result of high-grade drivers, precise voltage control, and meticulous calibration at the factory.

Electrical Reliability and Signal Integrity

The interface where the panel meets the system host is a zone where quality is rigorously tested. A good quality AA104VC15 features a robust and clean LVDS (or other) interface circuit. This ensures strong signal integrity, minimizing electromagnetic interference (EMI) and crosstalk that can lead to image noise, sparkles, or intermittent failures. The power circuitry within the module must be efficient and stable, providing clean, ripple-free power to the TFT array and backlight.

Electrical reliability also encompasses protection features. This includes safeguards against electrostatic discharge (ESD), power surge, and reverse polarity. The panel should operate flawlessly within its stated voltage range and exhibit low power consumption, a key factor in thermal management and system design. Consistent performance over the entire specified temperature range (e.g., -20°C to 70°C) is a hallmark of quality, indicating careful component selection and design for environmental stress.

Longevity and Environmental Robustness

Quality is measured over time. The mean time between failures (MTBF) rating offers a statistical glimpse into expected lifespan, but real-world longevity is determined by component aging. A high-quality backlight with premium LEDs will maintain its brightness output (lumen maintenance) far longer than a cheaper alternative, which may dim significantly within a few thousand hours. The liquid crystal materials must resist degradation from UV light and heat.

Environmental robustness is a non-negotiable aspect for industrial displays. A good AA104VC15 is designed to resist not just temperature extremes, but also humidity, condensation, and potentially corrosive atmospheres. Its construction should mitigate the effects of vibration and shock, common in mobile or heavy machinery applications. This durability is often validated through standardized testing (e.g., for vibration, shock, and thermal cycling), providing tangible proof of quality beyond mere claims.

The Manufacturing and Supply Chain Imprint

The genesis of a quality panel lies in its manufacturing process. A reputable manufacturer employs automated, precision assembly lines in a controlled cleanroom environment to minimize defects. Rigorous quality control (QC) and quality assurance (QA) protocols are in place, including 100% electrical testing and thorough optical inspection at multiple stages. Traceability is key; knowing the lot history of components allows for accountability.

Finally, the supply chain integrity directly impacts the quality you receive. Authorized distributors or direct purchases from the manufacturer guarantee genuine, factory-fresh components. The grey market risks counterfeit, refurbished, or rejected panels that fail to meet original specifications. A reliable supplier also provides comprehensive documentation, including detailed datasheets, mechanical drawings, and compliance certificates (like RoHS, REACH), which are themselves indicators of a quality-controlled product.

FAQs: Good Quality for the AA104VC15 LCD Panel

Q10: Can I replace a low-quality panel with a high-quality AA104VC15 easily?A: Mechanically and electrically, they are typically drop-in replacements if the interface and form factor match. However, the enhanced performance and reliability will be immediately evident.

Conclusion

Evaluating the quality of a display panel like the AA104VC15 is a multidimensional exercise that transcends a list of technical specifications. As we have explored, true quality is an amalgamation of superior materials and meticulous construction, validated by exceptional and consistent optical performance, underpinned by electrical reliability, and proven through environmental robustness and longevity. It is a characteristic imprinted at every stage, from the cleanroom manufacturing floor to the integrity of the supply chain that delivers the component.

For engineers, integrators, and procurement professionals, understanding these facets is not an academic pursuit but a practical necessity. Investing in a genuinely high-quality AA104VC15 LCD panel mitigates risk, reduces total cost of ownership by avoiding premature failures, and ensures the end product delivers a reliable, superior user experience. In the demanding landscape of industrial and professional applications, the display is the face of your technology—making its quality an investment in your product's reputation and success.